Industrialists and businessmen know the importance of a good prototype. It can sometimes be the deciding factor of getting huge funding or going broke. Good prototypes can make or break a company. This is well understood by modern-day industrialists and businessmen, but sometimes getting a prototype done before an important meeting can be tough. Before rolling out production, prototypes are required as fast as possible. In cases like these, designing a prototype can be tough and sometimes downright impossible. Enter rapid prototyping, a revolutionary new way of getting prototypes done rapidly and as fast as possible to meet the demands of a client. But what is it? How can it be achieved? Let us discuss in detail.

What Is Rapid Prototyping?

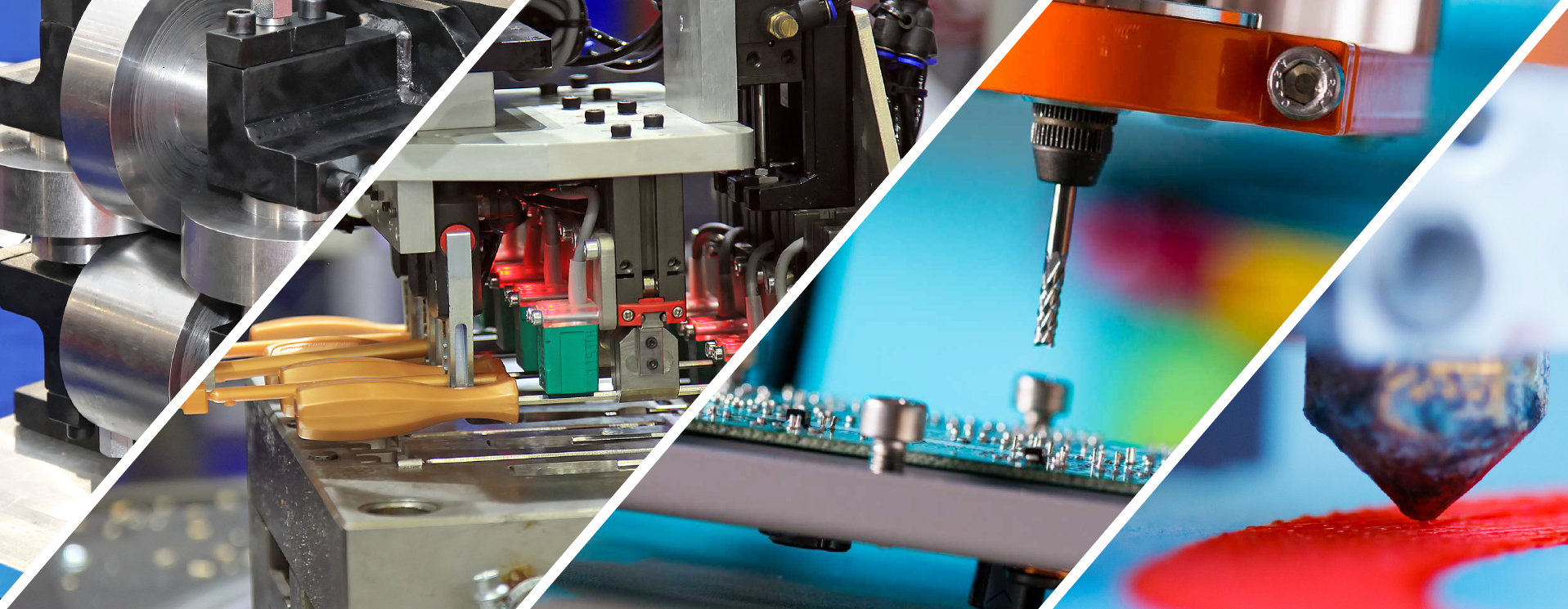

It is basically a procedure of designing, printing and rolling out a prototype of any product under a severe time constraint. Prototyping consists of Computer Aided Designing (CAD), to some extent 3-D printing and AutoCAD. All these processes work together to get the prototypes done as fast as possible within severe time constraints. This is basically the gist of rapid prototyping. This is essentially useful before starting out mass production of new products. The workers need a prototype to work with and the longer one takes to design a prototype the longer the work gets delayed. If one opts to rapidly build and design the prototype, then the procedure is sped up and mass production rolls out smoothly.

Rapid Prototypes – Advantages

While it may seem very obvious, this method of getting prototypes done proves to be very useful in certain cases. Let us try and understand those cases.

- This reduces the risk of making faulty mass-produced items. If a company designs something new and exciting, it cannot roll out production at once. It needs to do a lot of testing and designing before putting a product out for mass production. Here, rapid prototyping helps.

- This procedure also helps the R&D department of a company as it can rapidly test out and design any new products and test out its feasibility before handing out the design to the production team. New and improved products can be made within a relatively short period of time.

- It makes the process of making the client understand the product. Theoretical explaining can only get you so far with a client. Having an actual model to explain the product to a client makes things super simple and useful. Adding a prototype to a presentation exponentially improves the chance of landing a client’s order.

- Changes can be done to a product rapidly and more easily, ensuring improved products and fewer faults in the final products. To change the product, rapid prototyping is used widely across a lot of industries.

- It can help reduce the post-production costs for the company. This method not only reduces the usage of tools and properties to design a prototype but also reduces the time and effort that goes towards designing a prototype.